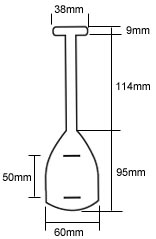

Black 'Wine Glass Shape' Equipment ID Tag

Rubber identification tags primarily designed for use in the identifying or inspection of lifting equipment

Our colour code rubber tags are extremely durable and will not fall or vibrate off accidentally. The tags should only be removed at colour change times when they can be put in to storage until the same colour rotates live once more.

- Individual tag weight: 14g

- Sold in packs of 50

- Other colours are available: Orange, red, grey, purple, emerald green, yellow, pink, sky blue, lime green, brown and now also spearmint or white.

By integrating a colour code system in to your a lifting and / or height safety scheme at the work place users will be able to instantly identify when the equipment was last examined by the competent person and therefore that the equipment should not be used.. For example January to March is RED, April to June is BLUE etc... Having 4 or more colours rotating in the colour code system means that if a piece of equipment goes missing when the inspection is due there is a good chance it will be re discovered before the same colour rotates live once more.

Colour code instant identification

To comply with LOLER 98 all lifting equipment and height safety equipment needs to be subjected to a thorough examination by a competent person at maximum intervals. Dependant on the piece of equipment the maximum period between inspections is either 6 or 12 months though it must be noted that this maximum period must be reduced dependant on how that equipment is used, the environment of use and by who / how often it is used (etc...).

Employers have a legal responsibility to maintain all lifting equipment in a good serviceable condition. It is the responsibility of the user of lifting and height safety equipment to perform a 'user inspection' of their equipment before and after use; (pre and post use inspection ensure two checks are carried out before the lifting gear is used) if any defect are detected the equipment should be immediately removed for service; thus preventing others from using the same potentially 'unsafe' equipment . The nominated person that is responsible for the lifting equipment scheme ensures all equipment reported as faulty is examined thoroughly by a competent person and any defects rectified or the equipment replaced. The competent person has the necessary practical and theoretical knowledge and experience to thoroughly examine, identify and rectify any faults (or return to others for rectification).

Dimensional Information